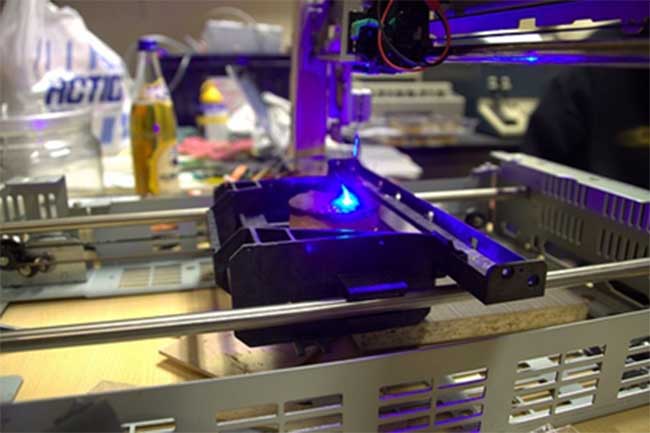

Laser is a mechanism that emits electromagnetic radiation as visible lights through a process known as stimulated emission. Due to an increased competition level in so many industries, companies have been forced to introduce advanced technology and thus implement laser system for various industrial applications like stamping, cutting, embossing, marking, and engraving. Laser marking technology is different from additional marking forms because of its unique combination of permanence, computer control flexibility, and speed.

The software employed for the laser marking system can only be accessed with a PCI interface card that delivers the digital signals of the etching file or computer-based marking to the motors, and thus points the laser beam in the direction of the product that it laser marked.

Some of the most used marking lasers are:

Lasers with CO2 – they create permanent codes meant for lifetime traceability; these reduce manufacturing costs and are easy to integrate with additional automated systems

Excimer Lasers – can be found in the subsequent UV laser wavelengths: 193nm, 248 nm, 157 nm, 352 nm, and 308 nm; mainly applied on Marking Eye Glasses, Inkjet Nozzle Drilling, and more.

YAG Lasers – commonly used as a base platform to produce different wavelengths when adequately configured. Infrared is the most versatile and common wavelength used to mark various materials such as composites, metals, plastics and ceramics.

Most popular marking methods in laser marking technology

Precipitation marking or annealing is frequently used when processing various metal items such as surgical instruments, surgical implants, or high-precision bearings. By using laser marking, the laser’s heat redistributes the material’s carbon and creates a jet black mark using only micron level surface interruption. When performed correctly, there’s no rusting or oxidation even under autoclaving or salt spray testing. Some plastic types such as Delrin and ABS can additionally permit a beautiful contrast when the processing laser makes use of 1,064 nm. Some of the most popular laser marking methods are:

Surface annealing

This method is meant to draw carbon or (and) oxides from the material base for obtaining a contrasting mark. Hence, the marking beam will be responsible for producing a sharp contrasting line to the surrounding area with no or very little penetration. The technique is great for applications where an undamaged, smooth contrast and surface are required. Surface annealing is commonly employed on tooling, bearings, and medical implanting.

Surface etching

The ability to modify reflectivity and boosting metal contrast by changing the metal’s surface finish is better known as surface etching. The method is an extremely common laser marking technique whose depth of penetration doesn’t go beyond 0.0001 inch deep.

Ablating

The method is employed by using backlit buttons, anodized aluminum, and painted steel, and it is employed to create contrast without having to damage the material’s base in any way.

Thermal marking

Thermal marking is based on controlling heat making use of different laser parameters like marketing speed, power, pulse frequency, and focus. The marking method is mainly utilized for various alloys whose final result is based on color variations.

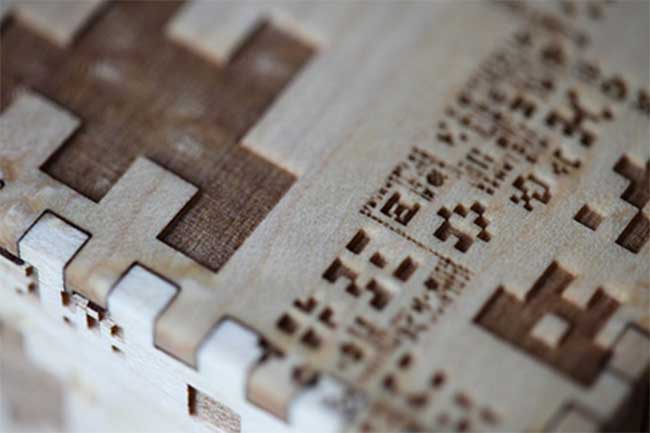

Engrave Marking

Engrave marking is produced through the vaporization of the base material, and it’s identical to surface etching. The depth used is usually, 0.0001 inch to 0.0005 inch. Repeating the technique leads to deeper marks.

Specialty marking

Last but not least, we have specialty marking, a method used in plastics. Don’t be surprised to see changes in contrast – that usually happens because of the coupling or heat of a wavelength that triggers chemical change. To achieve various colors, additives could be used with most plastic types. Product traceability is a really common type of specialty marking technique; it is described as a manufacturer’s ability to trace down a product by following its processing procedures and thus re-trace a certain product back to its manufacturer.

As far as laser marking machines are concerned, you might like to know that they’re extremely accurate and fast. A lot of branded manufacturers are able to offer a varied range of laser marking machines using spacious work areas and a superior metal engraving quality. Over the past few years, laser etching and laser marking have gained a lot of popularity in numerous business types, and that’s mainly because making is permanent, durable, and can’t be removed from a product without destroy it entirely.

Michael Clark wrote this article. He is a freelance writer covering the world of videogames, tech, and popular culture. He recommends www.fimark.co.uk for high quality service in laser marking.

Laser Marking Technology – A Popular Method used for Marking Parts,

Stephan

Jan 19. 2014

I know about this technique before but i don;t know it comes that far. I’m really impressed by engrave marking, maybe i have to research on it for my products.

thanks for your sharing.

stephan

Laser

Mar 28. 2014

Hello, I wonder if this technique of laser engraving can be made QR codes ?

Dinesh

Jul 20. 2017

Yeah definitely it can be done